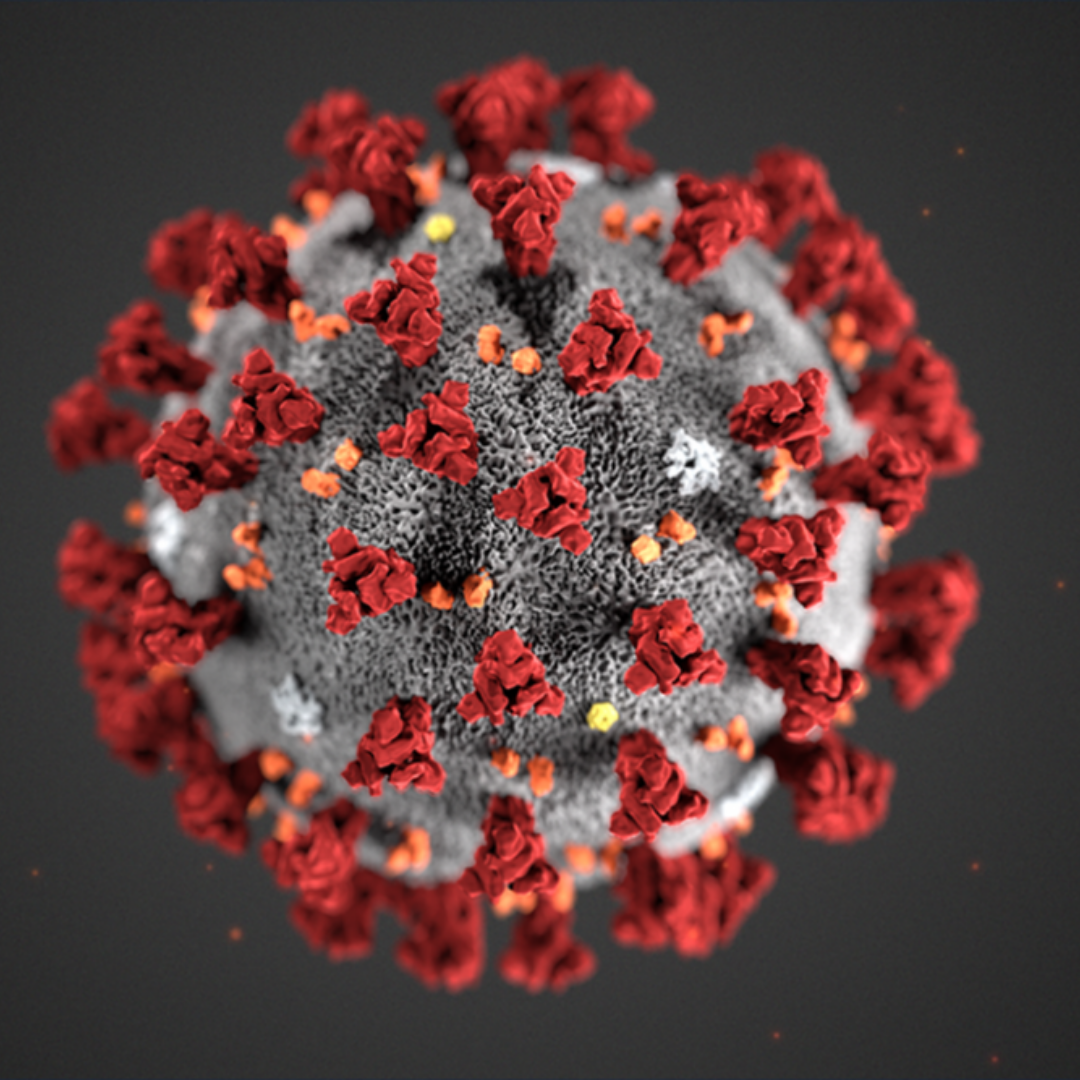

As the globe currently deals with the novel coronavirus pandemic, public interest in biological research has begun to grow. However, curative research takes time: drug discovery requires years of effort and financial resources to yield results. Even with focused endeavors, it would still take approximately two years for a CoV-2 vaccine to be available.

To reduce both the time and effort involved in drug discovery, the lab of Satish Nair, Interim Head of the Department of Biochemistry and Director of the Center of Biophysics and Quantitative Biology, is experimenting with a class of natural products called ribosomally synthesized and post-translationally modified peptides (RiPPs). These molecules are found in nature and made by all three branches of life. Importantly, several of these compounds have biological activity. Through high-throughput generation of RiPPs, researchers could potentially speed up and centralize the process of developing new long-lasting antibiotics, antifungals, and anticancer agents while also lowering development costs.

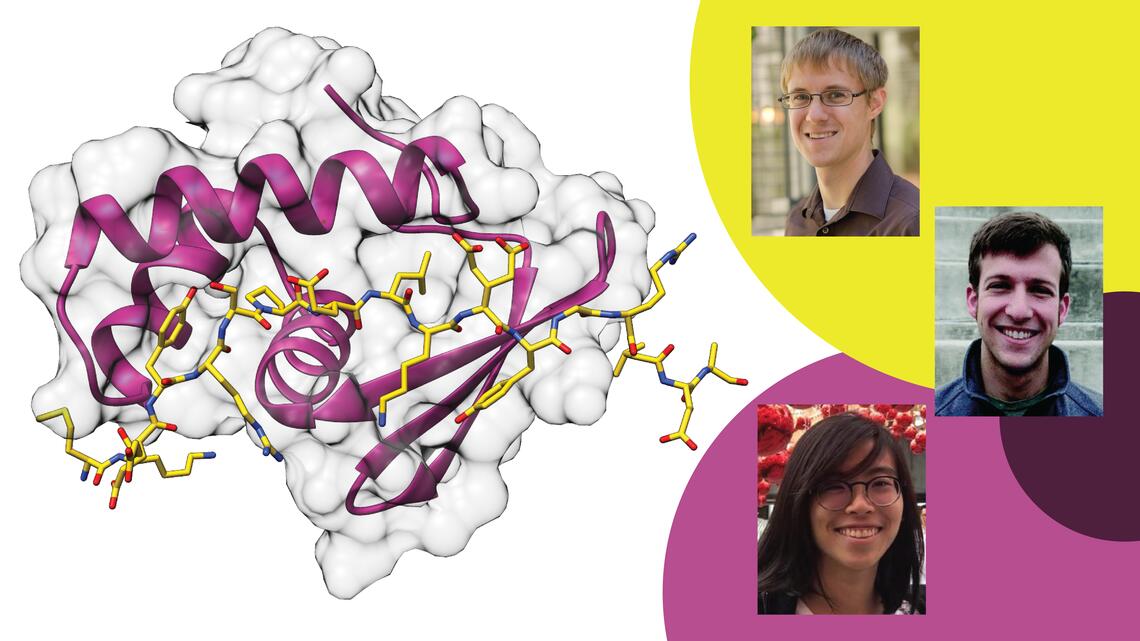

Nair’s lab published two papers in PNAS last year that provide insight into the nature of RiPPs: “Steric complementarity directs sequence promiscuous leader binding in RiPP biosynthesis” and “Characterization of glutamyl-tRNA-dependent-dehydratases using nonreactive substrate mimics” (in collaboration with Wilfred van der Donk’s lab).

“In the old days, when people looked to discover drugs, they would grow bacteria/fungi or take plant extracts and test them for activity. Did they kill cancer cells? Fungi? Bacteria?” Nair explained. Growing and testing each component took serious time, but the effort paid off in that era.

“At that point, it was easy to find new antibiotics because we hadn’t found many. But bacteria are very good at making themselves resistant to antibiotics. They can either destroy the antibiotic or figure out a way of changing it so that it no longer works. It’s an arms race between finding new drugs versus bacteria being able to inactivate them. Now, it takes pharmaceutical companies five or ten years to bring a drug to market. When that drug ends up having a shelf life of two years, then that’s not a viable business model,” Nair said.

“The best part of working in the RiPP field is that Illinois has some of the leading experts among our faculty.” Nair said adding that “Wilfred van Der Donk really pushed the field into the forefront, and Douglas Mitchell has come up with innovative tools to discover new classes of RiPPs.”

In comparison to existing drugs that are rapidly becoming outdated because of this bacterial arms race, classes of new natural antibiotic peptides are gaining prominence. Approved by the FDA as a food preservative since the 1950s, nisin is a famous example of a RiPP and is produced by bacteria that thrive in milk and cheese. “Surprisingly, although resistance to penicillin was apparent within a few years after its discovery, there’s limited resistance to nisin. In other antibiotics like penicillin or vancomycin, five to six years is the lead time between introduction into the clinic and the first signs of resistance,” Nair added.

Observations like these show that RiPPs may offer a potential edge over current antibiotics in terms of effectiveness and also in ease of development. Since every component of a RiPP is genetically encoded, scientists could simply insert the necessary genes into an artificial host like E. coli and trick the bacteria into producing the RiPP for them. “More importantly,” Nair said, “you can change every amino acid on the starting peptide, and then get E. coli to make every version of that molecule for you. That way, one can screen large libraries of compounds and produce a molecule with a desired activity.”

Pharmaceutical companies typically discover new drugs by compiling compound libraries and performing a barrage of tests to identify a single molecule. “If you ask a big company like Merck, their compound library has a few million compounds. That’s a large number, but for a 10-residue peptide, we could make 1012 number of molecules in E. coli! And we wouldn’t need to purify any single one of them. We’d get E. coli to make every one of them and then just pull out the one that has the property that we want,” Nair said.

This method works because RiPPs are composed of two parts: a leader sequence (which binds the peptide to a modifying enzyme), and a core sequence (which determines the RiPP’s biological function since it’s the site where the chemistry between the peptide and the enzyme happens). As long as the leader sequence is present, the peptide can bind to an enzyme even if its core sequence has been modified from its original form. That means that researchers can modify any amino acid in the peptide’s core sequence—or even swap the original core sequence with one that has a different function, like one that confers antibiotic capabilities—and expect it to bind to the enzyme in the same way an original, unmodified peptide would.

The Nair lab found that peptide with significant variants in the leader sequences can still bind to the modifying enzyme. “It was previously thought that the leader portion probably binds to the enzyme through specific interactions much like a key fitting into a lock,” Nair said. “We are able to show in that paper that it’s not specific interactions that occur, but mostly a narrow fit, like ball bearings fitting inside a bunch of troughs.” This means that scientists aren’t required to manufacture an exact sequence for the RiPP to bind to an enzyme: partial information will still allow the leader to bind, the same way that “the police could use a partial license plate to find who a car belonged to in old cop shows,” Nair supplied.

Nowadays, researchers have digital access to bacterial genomes, which allows them to search for genes that encode for proteins that display antibiotic properties or can disrupt protein-protein interactions. However, even though certain bacteria possess antibiotic-producing genes, they may not use them. “For some reason, the laboratory conditions that we grow the bacteria in are different enough from their natural environments that they don’t make these molecules even though they have the genetic capability of doing so,” Nair explained.

To investigate this problem, an IGB group composed of Nair, William Metcalf in Microbiology, Huimin Zhao in Chemical Engineering, Wilfred van der Donk in Chemistry, and Neil Kelleher (now at Northwestern University) worked on a 10-year long, NIH-funded project theme called “Mining Microbial Genomes” to explore the “digital dark matter of genomic data and figure out how many antibiotics could be made using computational approaches,” Nair said. Using that information, they hoped to insert sets of antibiotic-producing genes from one type of bacteria into another that could theoretically mass-produce those antibiotics. Even though that project has since expired, it sets the intellectual foundation for the papers Nair’s lab has published.

A newer utility of RiPPs is to design peptides that disrupt protein-protein interactions. “If you have a signaling pathway that ultimately results in cancer, you can generate a peptide that blocks the pathway, and you can do this all within E. coli without having to synthesize anything yourself,” Nair added.

Among all the current potential uses for RiPPs, the biotechnological aspects of reverse-engineering these peptides offer the most exciting ideas into how to fight diseases because they can speed up existing processes and centralize them into one method while also bringing development costs down. Nair said, “It would be cool to make a designer molecule by looking at, for example, the coronavirus and saying, ‘If we disrupt the interactions between a protein the viral surface that is essential for interacting with the host, then we have something that can essentially stall COVID-19.’ From that point on, we can reverse-engineer a peptide and put it together in a Frankenstein approach. All the enzymes that are necessary to make that sort of constrained peptide would do exactly what you would want them to do.”

In this way, development of RiPPs could bypass currently-existing limits on the manufacturing of antibiotics, antifungals, and anticancer drugs by easing the process and by opening up a world of possibilities as to how many different kinds of drugs can be made while also increasing their effectiveness.

These two papers were also written in collaboration with former MCB graduate students Dillon Cogan (currently a postdoctoral fellow at Stanford University for Chemical Engineering) and Jonathan Chekan (postdoctoral fellow at Scripps Institute and incoming faculty member at University of North Carolina at Greensboro), and current graduate student Chayanid Ongpipattanakul.